top of page

1. 1st an initial alignment is created & the part is inspected per print / GD&T.

2. A nominal and actual local coordinate system are created on the CAD & Scan.

3. Discrete inspection points are created on the manufacturing datums.

4. A subsequent RPS / Best Fit alignment is created on the critical features (to optimize dev)

5. A transformation matrix is extracted between the nominal and actual local coordinate system, along with the discrete inspection points.

6. This 'shift' can then be fed back into the manufacturing process so subsequent parts are made within tolerance. (toolpath and or fixture adjustment)

ADAPTIVE MANUFACTURING

- FEATURE OPTIMIZATION BY DATUM SHIFT -

By using the tools within GOM Inspect professional, we can create a transformation matrix that can be be used to adjust the physical part within a machining center to optimize a surface, or set of features such as a hole pattern.

This video has been deleted.

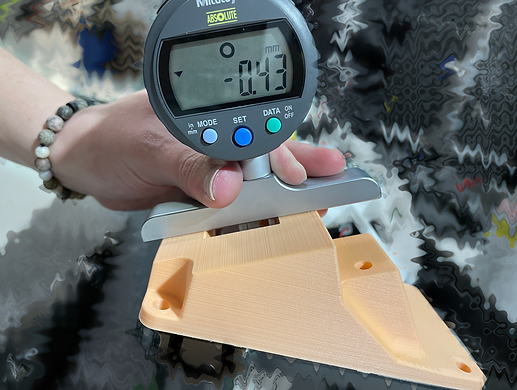

3D Printed Inspection Fixture

Go / No-Go & Depth Mic Version

Created with Fusion 360

Printed with Ultimaker II

Validated via CMM & Gage R&R

qc Above

atos

3d-Scanner

Proficient

with

GD&T

qc below

tri-top

photogrammetry

bottom of page